09/12/2023

QR codes can store a large amount of information. For this reason can be used as a new type of publicity means and marketing means, and it is now slowly becoming more and more business manufacturers to utilize.

The printing of two-dimensional code is also very easy, with ordinary laser marking machines that can easily be printed in bulk.

1)Non-contact processing: no need to contact the surface of the object to print. So it will not cause damage to the item at all.

2)Wide material applicability: it can be printed on a wide range of materials such as metal, plastic, ceramics, etc. So it is widely used.

3)Can be integrated with other equipment on the production line to improve the automation of the production line.

4)Marking is clear, lasting, beautiful, and can be effectively anti-counterfeiting. For two-dimensional code, it can be effective for a long time without breakage.

5) Long service life, no pollution; will not produce any waste gas, or wastewater.

6) low running costs Plug-in can be, depending on the size, the wattage is different, generally low. Marking speed and marking a molding, energy consumption is small, thus low operating costs. This saves a lot of cost for the business manufacturers who need to hit the two-dimensional code.

7) high processing efficiency: computer-controlled laser beam can move at high speed (5 - 7 m / s), marking process can be completed within a few seconds. 1 standard computer keyboard printing can be completed in 12 seconds. The size of a two-dimensional code is also so big.

8) Fast development: due to the combination of laser technology and computer technology. Users only need to program the computer to achieve laser printout.

They can change the print design at any time, which fundamentally replaces the traditional mould-making process, and provides a convenient tool to shorten the cycle of product renewal and flexible production. The QR code can be directly inputted into the computer according to the style.

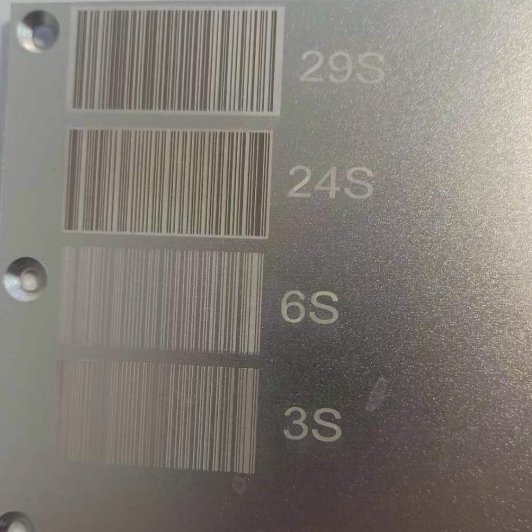

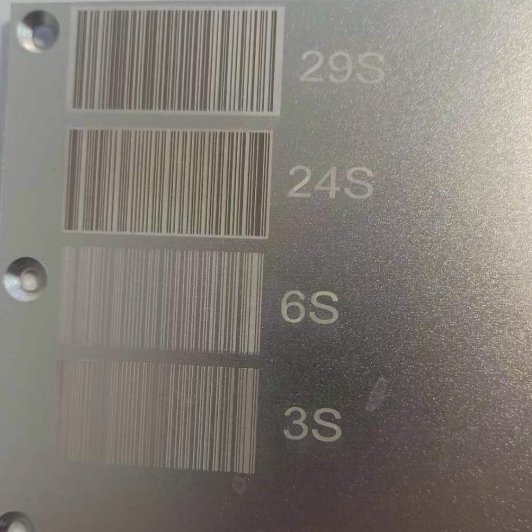

9) High processing precision: laser can act on the surface of the material with a very fine beam, the finest line width can reach 0.05mm, which creates a wide application space for precision processing and increased anti-counterfeiting function. Laser marking can meet the need to print large amounts of data on very small plastic parts. For example, it can print 2D barcodes that require greater precision and clarity, which is more competitive in the market compared to embossing or jet marking methods. Accurate multiple two-dimensional code is very important to ensure the integrity of the two-dimensional code printing to be more effective.

10) low maintenance costs: laser marking is non-contact marking, unlike the stencil printing marking process has a service life limit, in the batch processing maintenance costs are extremely low.

11) environmentally friendly: laser marking is non-contact marking, energy saving, as opposed to corrosion, to avoid chemical pollution; as opposed to mechanical marking, can also reduce noise pollution.

Email:[email protected]

Whatsapp: +86 13781961057

Bing Yan Laser tiktok: https://www.tiktok.com/@bingyanlaser

Bing Yan Laser Youtube: https://www.youtube.com/@bingyanlaser